Kairos Power

Lou Martinez Sancho is Vice President, Strategy & Innovation at Kairos Power. Peter Hastings is Vice President, Regulatory Affairs and Quality at Kairos Power.

Kairos Power employees like to build, and their ultimate aim is a commercial nuclear reactor in service in 2030. Specifically, they plan to build the Kairos Power fluoride salt-cooled high temperature reactor, or KP-FHR for short.

They say they are disruptors, and their novel advanced reactor technology aims to be cost competitive with natural gas in the U.S. energy market. That achievement will come from the method used by SpaceX, an iterative development process to build increasingly complex rockets, applied here to nuclear technology.

Kairos Power is on a fascinating journey. To find out more about this, PUF discussed what the company is up to, and it's a lot. Listen in as Lou Martinez and Peter Hastings envision the future.

PUF's Steve Mitnick: You are developing an innovative advanced nuclear technology. What is your technology and what drove you to put this company together to bring this technology to fruition?

Lou Martinez: Kairos Power is a mission-driven company. We are singularly focused on our efforts to commercialize an advanced reactor technology. What singular means is that we are only developing one technology, which is a fluoride salt-cooled high-temperature reactor. We need to do it in time to play a significant role in the fight against climate change.

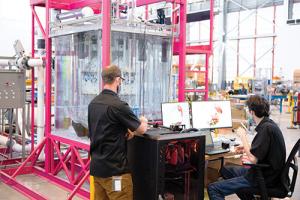

Engineers in the Rapid Analysis, Prototyping and Iterative Design Laboratory (RAPID Lab). R-lab is collocated with Kairos Power’s Alameda, California headquarters.

Engineers in the Rapid Analysis, Prototyping and Iterative Design Laboratory (RAPID Lab). R-lab is collocated with Kairos Power’s Alameda, California headquarters.

Kairos in Greek means the right or opportune moment. By the 2030s, there will be a lot of natural gas combined-cycle retirements in the U.S. and large nuclear reactors will need to be replaced.

Energy needs will continue to increase as our society grows. Therefore, we need to deliver a clean-energy solution with robust safety at an affordable cost.

PUF: Peter, how did you all get together and why did you do this?

Peter Hastings: Kairos Power grew out of an integrated research project, collaborating with DOE, UC Berkeley, MIT, University of Wisconsin-Madison, and National Laboratories.

Lou Martinez: ETU is going to be the largest Flibe facility ever built in the U.S. by an industrial company. After ETU, we have the Hermes demonstration reactor to prove we can deliver nuclear heat at an affordable cost. After Hermes, we’re moving to a full-scale, non-nuclear version of our first commercial reactor.

Lou Martinez: ETU is going to be the largest Flibe facility ever built in the U.S. by an industrial company. After ETU, we have the Hermes demonstration reactor to prove we can deliver nuclear heat at an affordable cost. After Hermes, we’re moving to a full-scale, non-nuclear version of our first commercial reactor.

Our three cofounders, all of whom worked on that project, concluded that the next logical step was to establish a private company to commercialize the fluoride salt-cooled high-temperature reactor to accelerate the development of an innovative nuclear technology to transform the energy market.

Our hybrid design uses TRISO fuel, which is virtually indestructible and has been demonstrated not to fail at temperatures that exceed our operating conditions — including postulated emergency conditions — by hundreds of degrees. It is coupled with a molten salt coolant, which has a tremendous heat capacity, chemical stability, and affinity for radionuclides.

In the unlikely event of fuel failure, where radionuclides leak out of the fuel, they're latched onto by the molten salt. You couple that with a primary system pressure that's, for all intents and purposes, atmospheric pressure, and it eliminates the volatilization component of a pressurized system.

You end up with a design that has orders-of-magnitude increases in safety over what is already the safest electricity technology ever developed. It's a no brainer.

Peter Hastings: In less than 2 years, we went from the decision to deploy that test reactor to acquisition and characterization of the site, development of the construction permit application, and submittal and acceptance of that application. To its credit, the NRC has kept up.

Peter Hastings: In less than 2 years, we went from the decision to deploy that test reactor to acquisition and characterization of the site, development of the construction permit application, and submittal and acceptance of that application. To its credit, the NRC has kept up.

PUF: There are always questions about nuclear safety cost. These are not thousand-megawatt plants that you're going to build.

Lou Martinez: A commercial unit of our advanced fluoride salt-cooled high-temperature reactor is expected to be a hundred forty megawatts electric. Different numbers of units can be combined together at any given site depending on the needs of the grid.

It's important to understand how our cost and safety case are related to the affordability of our reactor. What Peter just described is giving us incredible inherent safety. The combination of fluoride molten salt with TRISO fuel allows us to have an optimized nuclear safety footprint.

With our inherently safe design, we dramatically reduce the physical footprint of safety-related systems. That supports our objective to deliver clean energy at an affordable cost. We have four primary workstreams in which we are working hard to solve difficult problems and reduce risk in order to achieve cost certainty before building the first reactor.

First, we know to be cost competitive we must mitigate technical, licensing, manufacturing, and construction risk. To do so, Kairos Power is applying a rapid iterative development approach, which means building successive hardware iterations so we can learn by building.

We will have four major hardware iterations — nuclear and non-nuclear — prior to our first commercial reactor. That is one of our first strategies to prove cost certainty.

The second workstream is construction. We capture learnings and reduce construction risk as we build the different iterations.

The third workstream is the supply chain and manufacturing. We have a strong and vigorous vertical integration strategy for safety-related and critical components to ensure we achieve cost certainty.

The last workstream is licensing. We need to know the risks and have a high level of certainty that we can license our technology. If we have a high level of certainty on the technology, construction, supply chain, manufacturing, and licensing, we can translate that into a high level of certainty on the cost of the first nuclear reactor.

PUF: The NRC moves at a certain pace. How does that look? Are you optimistic?

Peter Hastings: I was heavily involved in the last large, light-water reactor renaissance as a member of the NuStart consortium where we worked to license AP1000 plants at seven sites under six different utilities.

Only two of them have gone to construction so far, and while I'm two-hundred-percent supportive of my friends and colleagues at the Vogtle plant, the outcomes at the other sites were not what anyone hoped for.

I've been doing exclusively nuclear work my entire career, nearly forty years, and the majority of that time has been in licensing nuclear facilities. I've never been as optimistic as I am now about the prospects of deploying new nuclear plants.

There's a new recognition of the value that nuclear energy brings to enabling the world's transition to clean energy. That's the nexus with our mission, not only among policymakers, but at the grassroots level as well.

We have worked with the NRC to ensure the agency is ready to receive and review applications for new technologies. Developments include establishment of a risk-informed regulatory framework for advanced reactors, right-sizing of emergency planning, security reforms, and more generic treatment of environmental reviews.

The NRC has adopted, and we've helped pilot, innovations that include streamlined review processes, increased use of in-office reviews and audits, and the core-team concept to provide for continuity during review from one year to the next.

In the past five years in the licensing space, we've set the pace for industry and pre-application engagement with the NRC. It's hard to say this without sounding like we're bragging, but we've submitted almost a dozen substantive, methodological topical reports, eight of which have been approved.

We've established all this while introducing an additional iteration in our iterative strategy — the deployment of a test reactor.

In less than two years, we went from the decision to deploy that test reactor to acquisition of the site, characterization of the site, development of the construction permit application, and submittal and acceptance of that application.

In forty years, I've never seen a case like that. To its credit, the NRC has kept up. I'm optimistic.

PUF: Lou, what are you building?

Lou Martinez: I have something cool to show you. This is a non-nuclear version of a fuel pebble that has been manufactured in our lab. We need a lot of them to make our reactor work. A single fuel pebble can produce the same amount of energy as burning four tons of coal, but without any carbon-dioxide emissions.

We are mirroring what SpaceX did with their rapid spiral development — we call our approach rapid iterative development — which allows us to accelerate test cycles for innovation and optimization.

The first big hardware demonstration we are building is the Engineering Test Unit, or ETU, which is going to be hot-commissioned in a few weeks in Albuquerque. It will perform integrated testing of a select set of systems, structures, and components in a non-nuclear and unenriched Flibe environment.

The scale of ETU is approximately the same as the Hermes demonstration reactor, for which we have submitted a construction permit application to the NRC. ETU is going to be the largest Flibe facility ever built in the U.S. by an industrial company.

The primary objective of ETU is to demonstrate design integration. We are already assembling a vessel, pump, pipes, and cooler stuff like pebble handling equipment, the reactivity control and shutdown system, and all our instrumentation.

ETU has helped us to initiate and exercise the supply chain for Hermes' specialized equipment and materials and figure out what we need to vertically integrate, versus what we are going to source from outside suppliers.

After ETU, we have the Hermes demonstration reactor in Oak Ridge, Tennessee. Its output will be thirty-five MWth, and it will not be connected to the grid. Very similar to ETU, we are building Hermes to prove we can deliver nuclear heat at an affordable cost and derisk the licensing path of KP-FHR technology.

After Hermes, we're moving again to a non-nuclear iteration called U-facility, or user facility. There, we will have a full-scale, non-nuclear version of our first commercial reactor. It will have the pump, the vessel, and all the other systems, and will be used as a training facility.

From U-facility, we will gain the ability to derisk operations and maintenance costs. We have built alliances with major utilities in the U.S., including TVA, Constellation, Southern Company, and also Bruce Power from Canada.

Our last iteration will be the first commercial reactor. It's a single-unit, one hundred forty megawatt electric KP-FHR. It's still an iteration because it will be the first-of-a-kind build, and we need to keep learning by building.

Within Kairos Power we have two streams of development: one is the product, and at the same time we are investing in the infrastructure needed to manufacture it and reduce costs. That's why we have our facilities here in Alameda, California with two labs.

There is the RAPID prototyping lab where we are constantly performing tests. Then, after we learn from an experiment, we dismantle it and build something new to keep learning. We also have the Salt lab where we design and build test cycles involving molten Flibe salt.

Albuquerque, New Mexico, is the home of ETU. It's also home to our manufacturing infrastructure. From welding to robotic CNC machines, we have all the basics to create those main components.

PUF: Peter, what is the timeframe and what obstacles are in front of you?

Peter Hastings: We'll have our Hermes test reactor operating by 2026 and it has a fairly short lifespan. Our first commercial plant is planned for 2030. One of the challenges we expect to have — a good problem — is keeping up with the order book after that.

In terms of obstacles, I wouldn't describe our needs as hurdles, because we believe most of what we need to do is doable. We do need regulatory certainty. We need continued support for out-of-the-box thinking with regard to issues that affect broad deployment of new technologies.

We need forward thinking in policies on issues such as supply chain. For example, how do we modernize quality assurance requirements to stand up the supply chain for nuclear components and recognize that some of the rules in place for the existing operating fleet are out-of-touch with modern practices?

We'd like to see contracting reform on programs such as the Advanced Reactor Demonstration Program, for which we were one of several awardees.

We have congressional support on improvements in licensing. We'd love these innovations to be administration-proof, and not subject to appropriation cycles. We need congressional support for infrastructure for development of high-assay, low-enriched uranium.

Utilities can buy lots of reactors and maintain steadfast support regarding their commitment to a low-carbon portfolio, including a recognition that green does not necessarily mean clean. More important than pursuing artificial targets on renewables is pursuing meaningful targets focused on clean energy, including nuclear.

We'd love to see progress at the state level. Not only continued support we've seen emerge fairly recently for maintaining the existing operating fleet, but also making sure those mandated portfolios around carbon reduction provide a seat at the table for nuclear technology.

PUF: Why should the industry keep an eye on Kairos Power?

Lou Martinez: We are disrupting the industry with our rapid iterative development and vertical integration strategies to deliver an energy solution that has robust safety with an affordable cost. As an industry, we have forgotten how to build things, and you need to build things to learn.

That is what makes the Kairos Power approach unique.

Peter Hastings: Throughout my career, I've tried to find the altruistic outlook, asking myself, what is the company I'm working for doing to make the world a better place? This company knocks the socks off of all previous companies I've worked for in that regard. We have a team of people who believe they're coming to work to help save the world.

We have set forth an audacious mission. I encourage anybody who's interested in Kairos Power to look for opportunities to engage with us. We will make the impression that this is a company they want to be in business with.

Lou Martinez: We have a hybrid workforce. We have nuclear engineers and non-nuclear engineers. We look broadly to build our team because, to embrace innovation, we need to explore things in a different way as we are trying to solve problems that have never been solved before.

Lead image: The Engineering Test Unit Demonstration Experiment (ETUDE) test stand validates integral hydrodynamics performance and pebble fuel recirculation methods, in Kairos Power’s R-Lab in Alameda, California.